Mastering PCB Test: A Beginner’s Guide

Are you new to the world of pcb test ? Don’t worry, I’ve got you covered! In this guide, we will explore everything you need to know about pcb testing and how it can help in product differentiation.

The Importance of PCB Board Testing

Before diving into the details, let’s understand why pcb board testing is crucial. Simply put, it ensures that your printed circuit boards are functioning correctly before they are integrated into a final product. By identifying any faults or defects early on, you can save time and resources in the long run.

During the testing process, various parameters such as voltage levels, signal integrity, and component functionality are evaluated. This helps guarantee that your PCBs meet quality standards and perform optimally once deployed in real-world applications.

The Different Types of PCB Tests

Now that we recognize its significance let’s explore some common types of tests performed on PCBs:

- In-Circuit Test (ICT): This test checks individual components’ functionality by applying electrical signals through each connection point on the board. It verifies if all components are properly soldered and functional.

- Flying Probe Test: As an alternative to ICT for low-volume production runs or prototypes without bed-of-nails fixtures available yet, flying probe test uses movable probes to make contact with specific points on the board for verification.

- Burn-In Test: This type of test involves subjecting assembled boards to elevated temperatures while running them under full load conditions for an extended period. It helps identify potential failures due to thermal stress before shipping products out.

- X-ray Inspection: X-ray inspection allows for non-destructive testing of hidden solder joints, ensuring proper connections and identifying potential defects such as shorts or voids that may affect the board’s performance.

- JTAG Boundary Scan Test: This test uses a standardized interface to access and control digital signals on a PCB. It helps verify interconnections between integrated circuits (ICs) and detect faults like open circuits or short circuits.

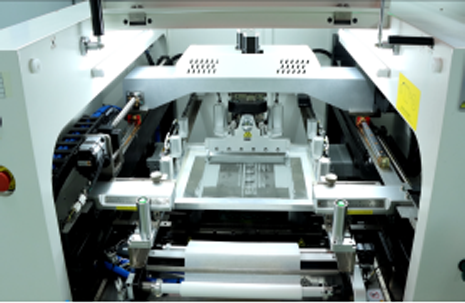

The JinHua Advantage

If you’re looking for reliable PCB testing services, look no further than JinHua! With their state-of-the-art facilities and experienced technicians, they offer comprehensive testing solutions tailored to your specific needs.

JinHua specializes in advanced automated testing techniques, including ICT, flying probe tests, burn-in tests, X-ray inspections, and JTAG boundary scan tests. Their commitment to quality ensures that your PCBs meet the highest standards before reaching the market.

In Conclusion

Mastering PCB test is essential for product differentiation. By thoroughly evaluating the functionality of your printed circuit boards through various tests like ICT, flying probe test, burn-in test, X-ray inspection, and JTAG boundary scan test – with assistance from experts like JinHua – you can ensure superior quality products that stand out from the competition.